Control Unit

| عنوان فارسی سری | عنوان انگلیسی سری |

|---|

AZUD FBC control Unit incorporates a whole set

integrating the detection, control and activation of the

backflushing cycle in the filtration Systems.

AUTONOMOUS FILTRATION SYSTEM.

The Control Unit is in charge of sending the signal to the Filtration Equipment to the making of the backflushing cycle. It allows to backflush when, how and during the necessary time according to the specific characteristics of each installation.

Electronic control system: PROGRAMMER

Its function is to control all the detection and activation functions.

Placed inside an electric cabinet with protection grade IP55.

Technical Specifications

| Controller | Allows the user to configure the number of filtration station and the self-cleaning cycle of each filtration station. |

|---|---|

| Display | Backlit digital display to show the filtration equipment status and the information about the self-cleaning of every filtration station. |

| Electrical box | IP65 with viewer, including the auxiliary components (transformer, relay, fuse and terminal connections). |

| Differential pressure gauge | With visual indicator and electrical switch for the backwash activation. |

| Solenoid | Pilot electrovalves for the backwash valves with hydraulic/pneumatic command. |

| Support | Metal / Plastic panel, which integrates the protection housing, differential pressure gauge and the valves solenoid. |

Other Features

| - |

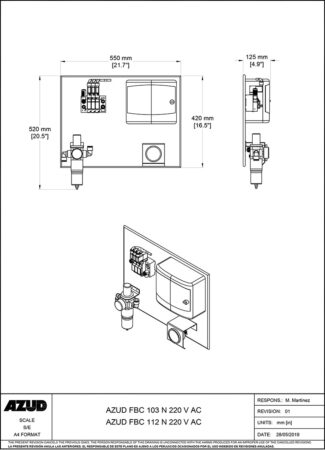

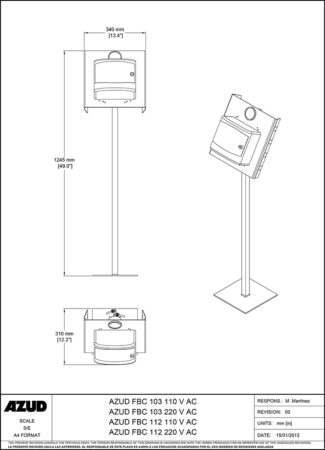

FBC 103/1…3 FBC 112/4…12 |

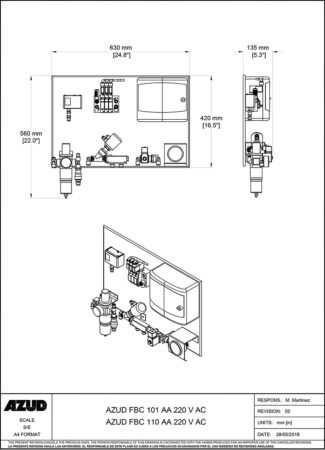

FBC 101/1 AA FBC 110/2…10 AA |

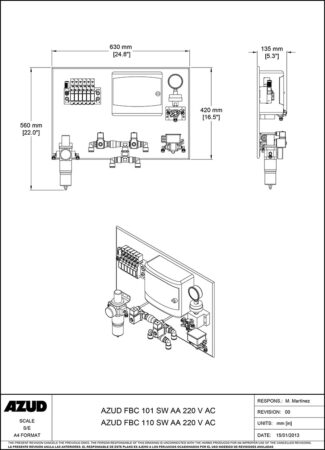

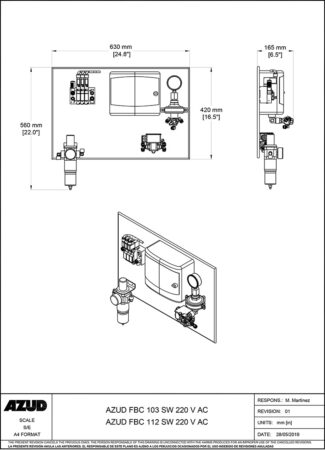

FBC 103/1…3 SW FBC 112/4…12 SW |

FBC 101/1 SW AA FBC 110/2…10 SW AA |

|---|---|---|---|---|

| Filtration equipment | FT200 DLP FT4DCL DLP | FT200 AA DLP | FT200 SW DLP FT4DCL SW DLP | FT200 SW AA DLP |

| Power supply | (Hz 60/50) AC V 110/220 | (Hz 60/50) AC V 110/220 | (Hz 60/50) AC V 110/220 | (Hz 60/50) AC V 110/220 |

| Operating voltage | Solenoid valves 24 V AC | Solenoid valves 24 V AC | Solenoid valves 24 V AC | Solenoid valves 24 V AC |

| N° of filtration station | FBC 103: 1-3 FBC 112: 4-12 | FBC 101 AA: 1 FBC 110 AA: 2-10 | FBC 103 SW: 1-3 FBC 112 SW: 4-12 | FBC 101 SW AA: 1 FBC 110 SW AA: 2-10 |

| Self-cleaning activation | Time, pressure differential, manual and/or external electrical signal | Time, pressure differential, manual and/or external electrical signal | Time, pressure differential, manual and/or external electrical signal | Time, pressure differential, manual and/or external electrical signal |

| Extra output 24 V AC | Included for sustaining valve command. With additional relay that informs about backwashing status of the equipment | Included for sustaining valve command. With additional relay that informs about backwashing status of the equipment | Included for sustaining valve command. With additional relay that informs about backwashing status of the equipment | Included for sustaining valve command. With additional relay that informs about backwashing status of the equipment |

| Digital input | Filtration real time counter, backwash start and backwash cancel (voltage free contact) | Filtration real time counter, backwash start and backwash cancel (voltage free contact) | Filtration real time counter, backwash start and backwash cancel (voltage free contact) | Filtration real time counter, backwash start and backwash cancel (voltage free contact) |

| Pressure differential gauge | 0.1 – 1.0 bar | 0.1 – 1.0 bar | 0.2 – 2.1 bar 0 – 10 bar manometer with membrane separator | 0.2 – 2.1 bar 0 – 10 bar manometer with membrane separator |

| Solenoid | 3-way NC. Hydraulic command | 4/2-way type. Pneumatic command 6 bar pressure regulator | 4/2-way type. Pneumatic command 6 bar pressure regulator | 4/2-way type. Pneumatic command 6 bar pressure regulator |

| Languages | English / Spanish or French / German | English / Spanish or French / German | English / Spanish or French / German | English / Spanish or French / German |

| Room temperature | (℉ 131) ℃ 55 ≥ | (℉ 131) ℃ 55 ≥ | (℉ 131) ℃ 55 ≥ | (℉ 131) ℃ 55 ≥ |

- It is possible for the manufacturer to change the technical specifications without prior notice.