AZUD LUXON LDB

| عنوان فارسی سری | عنوان انگلیسی سری |

|---|---|

| Standard series for low salinity water | LUXON LDB |

| Special series for seawater and high salinity water | LUXON LDB SW |

| Special series for drinking water with food grade | LUXON LDB DW |

| Special series for high pressure (16 Bar) | LUXON LDB PN16 |

Automatic electric screen filters suitable for all applications, and available in a wide range of micron sizes, all with the same high-quality guarantee of AZUD.

Filtration surface of up to 21300 cm² and a maximum flow (for 125 micron) of up to 1065 m³/h. The cleaning mechanism includes suction nozzles.

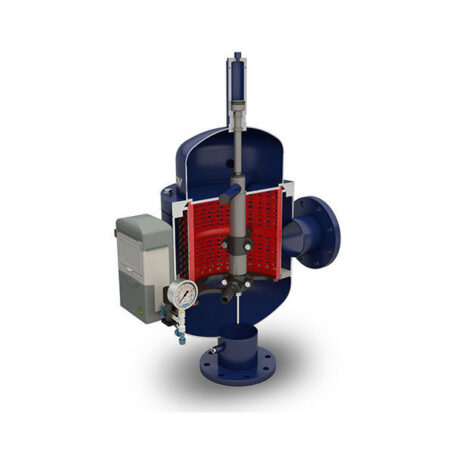

TECHNOLOGY

AZUD LUXON filters continue to supply filtered water without interruption during the flushing cycle. The water flows through the inlet and enters through the pre-filter to the inside of the filter element. The water then passes through the screen, and the particles are retained on the inside of the filter element (screen). The filtered water then flows out through the outlet. When the pressure differential from inlet to outlet of the filter reaches the pre-selected level, the flushing cycle starts (ΔP). A hydraulic valve opens in the drain port, which initiates suction in the inner nozzles. This, along with the helical movement up and down the screen sucks the captured particles into the waste flow, and this is expelled out the drain port. The length of the flush cycle e is pre-determined by the control unit. When the cycle is complete the flush valve closes and the flushing ends. The flushing process uses a minimal amount of water.

Technical Specifications

| Filter Type | Automatic screen filter (self-cleaning system) |

|---|---|

| TDS range | TDS < 6000 mg/l |

| Working pressure | Max: 10 bar (145 psi) Min: 0.8 bar (11.6 psi) |

| Min. flushing pressure | 2 bar (29 psi) |

| PH | 5 – 9 |

| Water temperature | ≤ 60 ℃ (140 ℉) |

| Filtration degrees | Screen with molded polypropylene support – 1000 – 500 – 300 – 200 – 125 – 100 – 80 – 50 (micron), Screen with PVC support * 1000 – 500 – 300 – 200 – 125 – 100 – 80 (micron), Screen with SS 304 support – 1000 – 500 – 300 – 200 – 125 – 100 – 80 – 50 (micron) |

| Connections type | Flange ANSI B16.5, Flange DIN 2576 |

Other Features

Command : Electric motor command

Axis position : Vertical

Connection configuration : Angle

Body : Carbon steel with internal and external epoxy-polyester coating. PN10

Cartridge : SS 316L weave wire screen with PVC or molded PP or SS 304 support

Flushing Device : Motor, gearbox and SS304 scanner with PVC or SS304 suction nozzles

Inlet/Outlet connections : Ø 2”-20” (50-500 mm) – Flange (DIN 2576 / ANSI B16.5)

Drainage valve connection : Ø1” (32 mm) BSP thread of reinforced polyamide or Ø2” (50 mm) grooved / BSP thread of reinforced polyamide or brass according to model – Hydraulic activation

Exhaust valve : Diaphragm 2-way valve

Manometer : ¼” BSP glycerine manometer male thread. bar/psi double scale (0-10 bar / 0-145 psi)

Control unit : AZUD FBC

Power supply : 380 V AC Three-phase / 220 V AC single-phase / 110 V AC single-phase

| Model | Filtration Area (cm2) | Connections Inlet/Outlet | Max. flow rate m3/h (gpm) - 125 micron | Max. flow rate m3/h (gpm) - 80 micron | Flushing flow rate x duration | Weight (empty) kg | Dimensions - L – W – H (mm) |

|---|---|---|---|---|---|---|---|

| * SS 316L screen with PVC support | |||||||

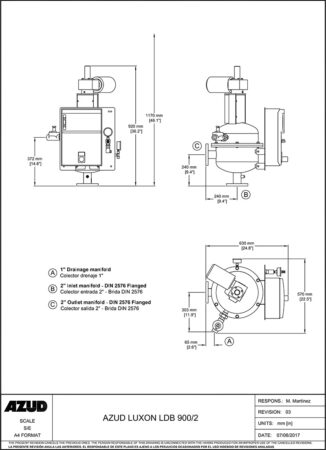

| LDB 900/2 LDB 900/3 | 900 | Ø2”

Ø3” | 30 (132) 45 (198) | 27 (119) 27 (119) | 0.7 l/s (11 gpm) x 8 s | 55 | 630 – 570 – 920 |

| LDB 1600/3 LDB 1600/4 | 1600 | Ø3”

Ø4” | 50 (220) 80 (352) | 48 (211) 48 (211) | 1.0 l/s (16 gpm) x 16 s | 60 | 630 – 575 – 1015 |

| ** SS 316L screen with molded Polypropylene support | |||||||

| LDB 2400 M/4 LDB 2400 M/6 | 2400 | Ø4”

Ø6” | 90 (396) 120 (528) | 72 (317) 72 (317) | 1.1 l/s (17 gpm) x 18 s | 80 | 700 – 620 – 1120 |

| LDB 4800 M/4 LDB 4800 M/6 LDB 4800 M/8 | 4800 | Ø4” Ø6” Ø8” | 90 (396) 170 (749) 240 (1057) | 90 (396) 144 (634) 144 (634) | 2.5 l/s (40 gpm) x 21 s | 100 | 700 – 710 – 1395 |

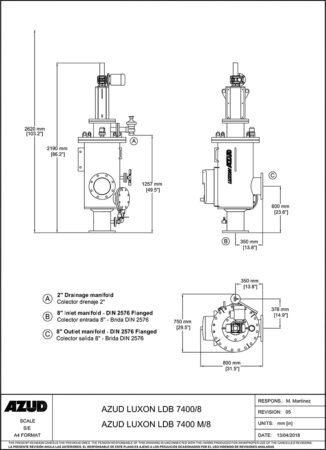

| LDB 7400 M/6 LDB 7400 M/8 LDB 7400 M/10 | 7400 | Ø3”

Ø8” Ø10” | 170 (749) 300 (1321) 370 (1629) | 170 (749) 222 (978) 222 (978) | 4.5 l/s (71 gpm) x 25 s | 360 | 800 – 750 – 2190 |

| LDB 9800 M/8 LDB 9800 M/10 LDB 9800 M/12 | 9800 | Ø8” Ø10” Ø12” | 300 (1321) 90 (2157) 490 (2157) | 294 (1295) 294 (1295) 294 (1295) | 5.8 l/s (92 gpm) x 25 s | 400 | 800 – 750 – 2470 |

| LDB 12300 M/10 LDB 12300 M/12 LDB 12300 M/14 LDB 12300 M/16 | 12300 | Ø10” Ø12” Ø14” Ø16” | 500 (2202) 615 (2708) 615 (2708) 615 (2708) | 369 (1625) 369 (1625) 369 (1625) 369 (1625) | 7.2 l/s (114 gpm) x 25 s | 450 | 800 – 750 – 2740 |

| *** SS 316L screen with SS 304 support | |||||||

| LDB 1000 S/2 LDB 1000 S/3 | 1000 | Ø2” Ø3” | 30 (132) 50 (220) | 30 (132) 30 (132) | 0.7 l/s (11 gpm) x 8 s | 55 | 630 – 570 – 920 |

| LDB 1800 S/3 LDB 1800 S/4 | 1800 | Ø3” Ø4” | 50 (220) 90 (396) | 50 (220) 54 (238) | 1.0 l/s (16 gpm) x 16 s | 60 | 630 – 575 – 1015 |

| LDB 2700 S/3 LDB 2700 S/4 LDB 2700 S/6 | 2700 | Ø3” Ø4” Ø6” | 50 (220) 90 (396) 135 (594) | 50 (220) 81 (357) 81 (357) | 1.1 l/s (17 gpm) x 18 s | 80 | 700 – 620 – 1120 |

| LDB 5400 S/4 LDB 5400 S/6 LDB 5400 S/8 LDB 5400 S/10 | 5400 | Ø4” Ø6” Ø8” Ø10” | 90 (396) 170 (749) 270 (1189) 270 (1189) | 90 (396) 162 (713) 162 (713) | 2.5 l/s (40 gpm) x 21 s | 100 | 700 – 710 – 1395 |

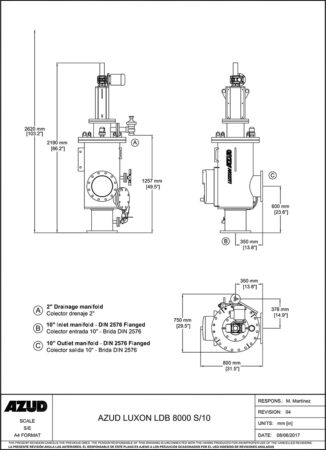

| LDB 8000 S/6 LDB 8000 S/8 LDB 8000 S/10 | 8000 | Ø6” Ø8” Ø10” | 170 (749) 300 (1321) 400 (1761) | 170 (749) 240 (1057) 240 (1057) | 4.5 l/s (71 gpm) x 25 s | 360 | 800 – 750 – 2190 |

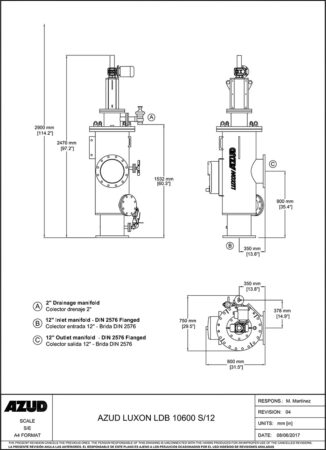

| LDB 10600 S/8 LDB 10600 S/10 LDB 10600 S/12 LDB 10600 S/14 | 10600 | Ø8” Ø10” Ø12” Ø14” | 300 (1321) 500 (2202) 530 (2334) 530 (2334) | 300 (1321) 318 (1400) 318 (1400) 318 (1400) | 5.8 l/s (92 gpm) x 25 s | 400 | 800 – 750 – 2470 |

| LDB 13200 S/8 LDB 13200 S/10 LDB 13200 S/12 LDB 13200 S/14 LDB 13200 S/16 | 13200 | Ø8” Ø10” Ø12” Ø14” Ø16” | 300 (1321) 500 (2202) 660 (2906) 660 (2906) 660 (2906) | 300 (1321) 396 (1744) 396 (1744) 396 (1744) 396 (1744) | 7.2 l/s (114 gpm) x 25 s | 450 | 800 – 750 – 2740 |

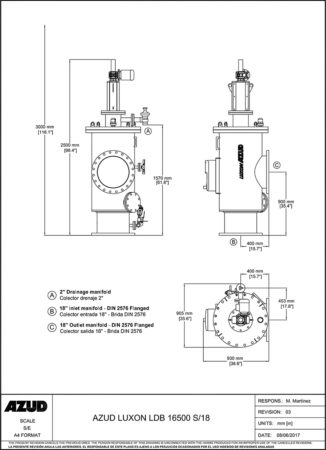

| LDB 16500 S/8 LDB 16500 S/10 LDB 16500 S/12 LDB 16500 S/14 LDB 16500 S/16 LDB 16500 S/18 | 16500 | Ø8” Ø10” Ø12” Ø14” Ø16” Ø18” | 300 (1321) 500 (2202) 700 (3082) 825 (3633) 825 (3633) 825 (3633) | 300 (1321) 495 (2180) 495 (2180) 495 (2180) 495 (2180) 495 (2180) 495 (2180) | 7.2 l/s (114 gpm) x 25 s | 550 | 930 – 905 – 2500 |

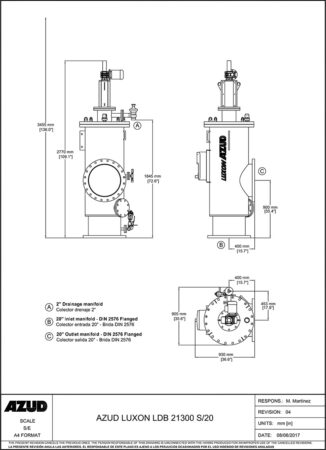

| LDB 21300 S/10 LDB 21300 S/12 LDB 21300 S/14 LDB 21300 S/16 LDB 21300 S/18 LDB 21300 S/20 | 21300 | Ø8” Ø10” Ø12” Ø14” Ø16” Ø18” Ø20 | 500 (2202) 700 (3082) 850 (3743) 1065 (4690) 1065 (4690) 1065 (4690) | 500 (2202) 639 (2814) 639 (2814) 639 (2814) 639 (2814) 639 (2814) | 7.2 l/s (114 gpm) x 25 s | 700 | 930 – 905 – 2770 |

- Maximum flow for good quality water.

- It is possible for the manufacturer to change the technical specifications without prior notice.